The Role of Patch Windows in Custom Box Making

In today’s competitive market, packaging isn’t just about protecting the product—it’s about showcasing it. One innovative way to strike a balance between protection and visibility is by incorporating patch windows into custom boxes. These transparent windows, typically made from PVC, offer a visual glimpse of the product while maintaining structural integrity and brand appeal.

This article explores how patch windows elevate the packaging game, especially when used in various tuck box styles such as straight end, reverse end, snap lock, and auto-lock tuck boxes. We’ll also examine how window-patched boxes are used across diverse industries including food, bakery, toys, cosmetics, electronics, soaps, and auto parts.

What Are Patch Windows in Packaging?

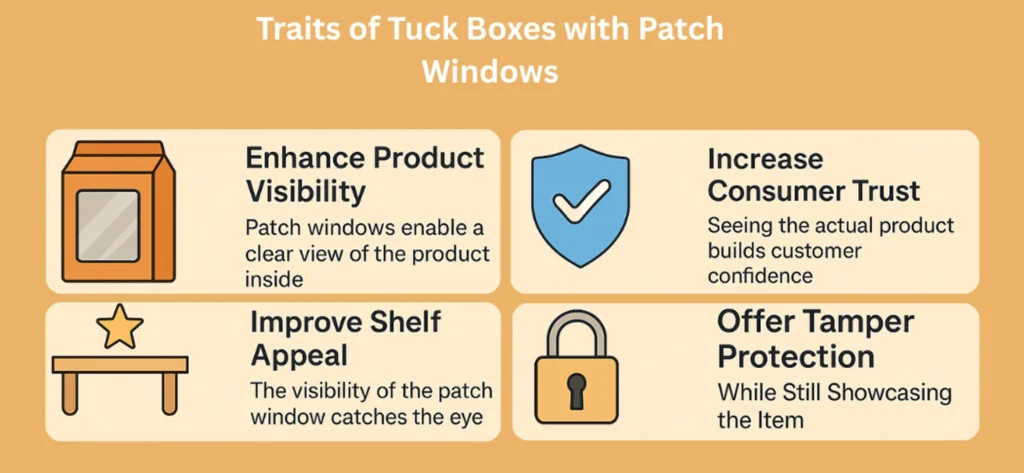

A patch window refers to a clear plastic or film insert that is adhered to a die-cut opening on a paperboard box. Unlike open windows, a patch window offers visibility without exposing the product to external elements. The window patch technique brings along these benefits:

Patch Windows in Tuck Box Styles

Tuck boxes are widely regarded as one of the most adaptable and practical packaging styles available across various industries. Their name comes from the way the flaps “tuck” into the box to close it, making them easy to assemble, stack, and store. What makes tuck boxes particularly valuable is their compatibility with a wide range of design customizations—including the addition of patch windows (Read our article about 5 Popular types of Die Cut Window Boxes). These transparent film inserts can be added to die-cut areas on the box, allowing customers to see the product inside without opening the packaging.

This visibility not only enhances the aesthetic appeal of the product but also builds consumer trust, especially for items where appearance or quality is a key selling point. Tuck boxes come in several structural styles—such as straight end, reverse end, snap lock, and auto-lock—each offering unique functional benefits. When combined with a patch window, these different tuck box styles serve specific needs based on product size, weight, and industry. For example, a straight end tuck box with a window is great for cosmetics, while a snap lock tuck box with a window is better suited for toys or auto parts. Let’s explore how each type of tuck box can enhance patch window packaging.

Let us now explore how patch windows in tuck boxes can be used for different tuck box styles.

Straight End Tuck Boxes with Windows

Straight end tuck boxes, are a popular packaging style known for their clean, professional appearance and practical design. In this style, both the top and bottom flaps tuck in the same direction, usually toward the back of the box. This creates a uniform and seamless front panel that’s perfect for branding, product images, or patch windows.

The symmetrical layout of a straight end tuck box allows for a balanced design, making it visually appealing on retail shelves. Because the flaps are tucked in the same direction, there are no interruptions or overlaps on the front-facing side of the box. This uninterrupted surface makes it an ideal space for adding window patches, giving customers a clear view of the product inside without affecting the structural integrity or the aesthetic layout.

Straight end tuck boxes are commonly used for cosmetics, skincare products, electronics accessories, small toys, and gourmet foods—essentially any product that benefits from strong shelf presence and attractive presentation.

Reverse End Tuck Boxes with Windows

Reverse end tuck boxes are a clever variation of standard tuck boxes, distinguished by their opposing flap closures—the top flap tucks in from one side, while the bottom flap tucks in from the opposite side. This design adds an extra layer of security and structural balance, making these boxes slightly more tamper-resistant than straight end tuck boxes.

Because the flaps open on opposite ends, it becomes more difficult for someone to open both flaps quickly or discreetly without noticeable damage to the packaging. This makes reverse end tuck boxes a smart choice for products that require a bit more protection or where authenticity assurance is important—like electronics, personal care products, pharmaceuticals, or collectible items.

In terms of presentation, the reverse tuck design still offers a clean front panel that can accommodate branding, graphics, and window patches. The structural layout is ideal for lightweight to medium-weight items and offers easy manual or automated assembly. Reverse end tuck boxes can be designed with locking tabs or tamper-evident seals, further enhancing their protective features.

Snap Lock Tuck Boxes with Windows

Snap lock tuck boxes are a sturdy and reliable packaging style specifically designed to hold heavier or bulkier products. What sets them apart is their interlocking bottom flaps—usually four flaps that fold and lock into one another to create a strong base without the need of glue or adhesive tapes.

Because of this built-in strength, snap lock tuck boxes are ideal for items that need more structural integrity during storage, handling, or shipping. For example, toy sets, glass containers, auto parts, small electronics, or gourmet gift items often use this type of packaging.

In addition to durability, snap lock tuck boxes can also accommodate patch windows on the front or top panels. This allows the product to be showcased attractively, while the reinforced base safely supports the item’s weight. This combination of functionality and visual appeal makes snap lock tuck boxes a preferred choice for many retail-ready, moderately heavy products.

Auto-lock Tuck Boxes with Windows

An auto-lock tuck box (also called an auto-bottom box) is a smart packaging design that features a pre-glued, collapsible bottom panel. When the box is opened, the bottom automatically locks into place without the need for manual folding or additional adhesives. This feature significantly speeds up the packaging process, making it highly suitable for high-volume, fast-paced assembly lines—especially in industries like food, cosmetics, toys, and electronics.

The auto-lock mechanism provides a secure and reinforced base, making it ideal for holding heavier or more delicate items. Unlike basic tuck end boxes, which rely solely on folded flaps for structure, the glued bottom offers greater weight-bearing strength and resistance to collapse. This makes it perfect for products like baked goods, candles, jars, cosmetic sets, or small tech gadgets.

Additionally, the flat shipping design of auto-lock tuck boxes saves on storage space and shipping costs. And like other box types, they can easily incorporate patch windows to enhance product visibility.

Industry Applications of Patch Window Tuck Boxes

Now let’s look at how patch windows are used across industries to boost consumer experience and branding for tuck boxes.

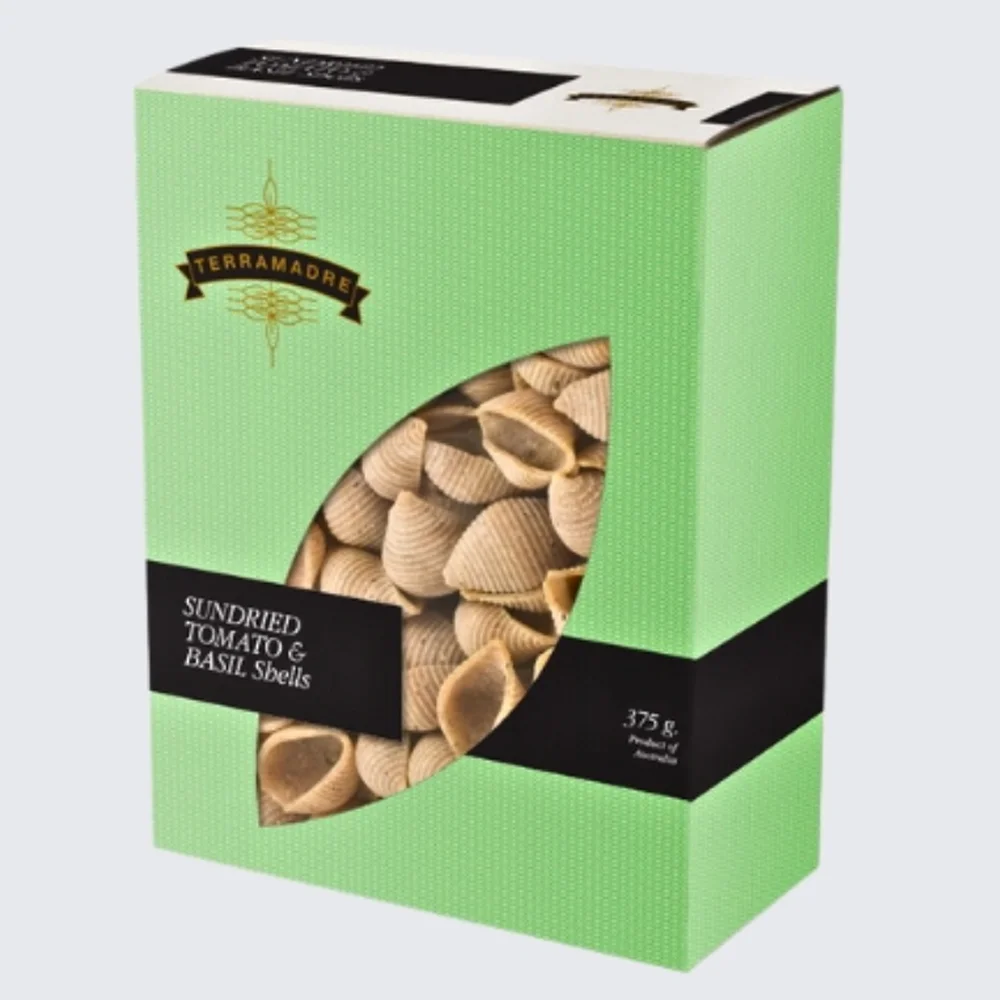

Food Packaging

Patch windows in food packaging serve more than just a decorative purpose—they play a vital role in communicating freshness and product quality to consumers. By offering a transparent view of the contents, they allow customers to visually inspect the texture, color, and condition of the food before purchasing. This builds trust, especially in items like baked goods, cereals, or snacks, where appearance influences buying decisions. The protective film also keeps the product safe from contamination, maintaining hygiene while still enhancing shelf appeal through visibility and transparency.

Custom cereal boxes or granola packaging with small transparent windows allow buyers to see the mix of grains, nuts, and dried fruits.

Straight end tuck boxes with a side patch window can be used for snack bars, showcasing the texture and ingredients inside.

Snap lock tuck boxes are commonly used for frozen food, like spring rolls or nuggets, with a fog-resistant PET patch window.

Bakery Packaging

In the bakery industry, visual appeal plays a major role in attracting customers. The ability to see fresh, beautifully crafted treats can trigger impulse purchases and build trust in product quality. Window-patched boxes are an ideal packaging choice because they offer a clear view of the baked goods—such as cupcakes, cookies, or pastries—without opening the box. This not only maintains hygiene but also enhances presentation. By showcasing texture, freshness, and decoration through a transparent window, bakeries can increase perceived value and improve sales potential right at the point of purchase.

Auto-lock tuck boxes with a large top patch window are ideal for cupcakes, muffins, and donuts as shown in the image below.

Straight end tuck boxes with side windows are often used for loaf cakes or biscotti, providing a stylish presentation while maintaining shelf-life.

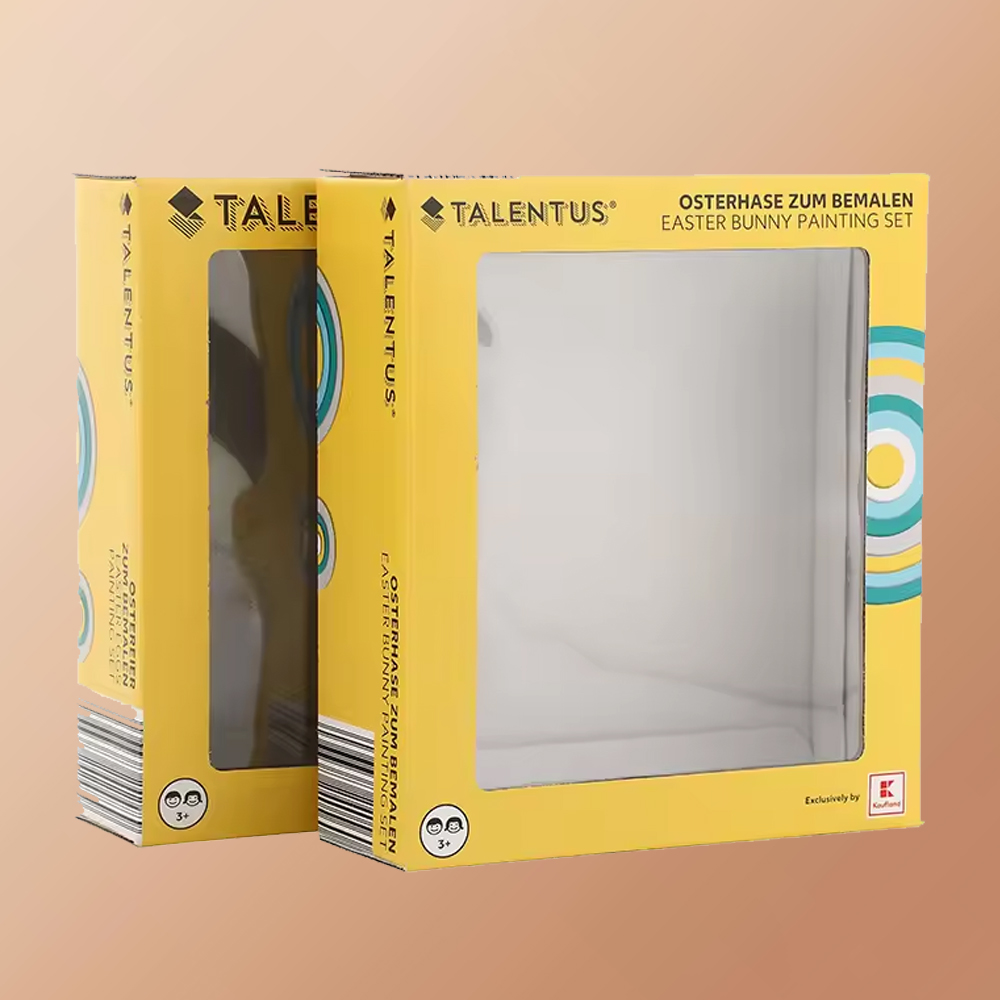

Toy Packaging

When it comes to toys, visibility drives excitement and trust. Both parents and children are more likely to choose products they can see clearly before buying. Patch windows allow toy manufacturers to showcase the actual product—its colors, features, and size—through a transparent section of the box. This helps communicate the toy’s purpose, quality, and appeal instantly, without opening the packaging. Whether it’s an action figure, puzzle, or craft kit, seeing it upfront builds confidence in the purchase and often encourages impulse buying, especially in retail environments where visual impact matters most.

Snap lock tuck boxes with large PVC windows are perfect for action figures, dolls, or puzzle pieces.

Reverse end tuck boxes are used for collectible card games and educational kits, with a small circular window to give a sneak peek of the contents.

Cosmetics and Skincare Packaging

In the cosmetic industry, product appearance is a major factor in purchasing decisions. Customers often want to see the exact color of a lipstick, the texture of a foundation, or the shape of a compact before committing to a buy. Window-patched packaging meets this need by offering a clear, protective view of the product inside. It allows brands to showcase their items in a visually appealing way while maintaining hygiene and security. This not only builds consumer trust but also enhances the luxury feel and shelf appeal of the packaging, influencing both interest and conversion.

Straight end tuck boxes with die-cut windows are used for lipsticks, compact powders, and eyeshadow palettes.

Reverse end tuck boxes are preferred for serums, essential oils, and mascara tubes.

Electronics Packaging

For small electronic gadgets and accessories, like USB drives, chargers, or earphones, both protection and visibility are essential. Consumers want to inspect the product before purchase, but also expect it to be secure and tamper-proof. Window-patched tuck boxes offer the perfect solution—combining a clear view of the item with sturdy, enclosed packaging. The transparent window lets buyers verify the product’s design or color, while the sealed structure prevents damage or theft. This balance of security and showcase not only builds consumer confidence but also enhances retail presentation, especially in tech stores or electronic aisles.

Reverse end tuck boxes with narrow slit-style windows are often used for power banks, USB drives, and adapters.

Snap lock tuck boxes are great for slightly heavier items like Bluetooth speakers or LED bulbs.

Auto Parts Packaging

Surprisingly, even the automotive parts industry benefits from the use of patch windows in packaging. When selling small components like spark plugs, filters, or fuses, being able to visually inspect the product without opening the box helps both consumers and mechanics ensure they’re getting the right part. Window-patched tuck boxes allow for quick identification while keeping the item protected from dust, damage, or tampering. This improves customer confidence, reduces return rates, and enhances the overall shopping experience. In a sector where precision matters, visibility through patch windows adds real value to automotive packaging.

Snap lock tuck boxes with durable PET windows are used to showcase filters, spark plugs, and gaskets.

Auto-lock tuck boxes provide added strength for bulkier parts while still showing product shape and size.

Soap Packaging

In handmade and artisanal soap packaging, visual appeal is key to showcasing the product’s craftsmanship and natural ingredients. Customers are often drawn to the unique textures, vibrant swirls, and embedded herbs or botanicals that set handmade soaps apart. Window-patched boxes allow shoppers to admire these details without compromising hygiene or protection. The transparent window provides a sensory preview, enhancing trust in product quality and authenticity. For brands focused on natural or eco-friendly values, this visibility helps communicate transparency and care, ultimately influencing purchase decisions and creating a more engaging customer experience.

Straight end tuck boxes with a uniquely shaped window (e.g., leaf, circle, oval) offer both aesthetics and product visibility.

Auto-lock tuck boxes with large top windows can be used for bundled soap sets or bath bombs.

Designing Window-Patched Tuck Boxes: Tips for Success

Designing an effective patch window tuck box requires a thoughtful balance of form, function, and branding. To make the most impact, start with strategic window placement—position the patch window where it highlights the most attractive or important part of the product, such as a label, color, or texture. This gives customers a clear and compelling view without opening the box.

Next, consider using custom-shaped die-cuts instead of standard rectangles. Unique shapes like circles, hearts, or brand-themed outlines not only draw attention but also help reinforce brand identity. As you can view from the images below.

Ensure that the print design complements the window, not competes with it. Keep the surrounding graphics clean and minimal to allow the product to take center stage. Lastly, add tamper-evident features like seals or perforations to build trust and maintain product integrity. When done right, patch window tuck boxes do more than just look good—they enhance the unboxing experience, communicate transparency, and directly influence purchasing behavior.

Finally the conclusion about Tuck Boxes with Patched Windows

Patch windows have evolved far beyond being a simple decorative element on packaging—they now play a vital role in both the functionality and marketing strategy of modern product presentation. When thoughtfully integrated into custom tuck box designs, these transparent windows not only enhance visual appeal but also significantly improve the consumer’s interaction with the product before purchase. Whether applied to straight end, reverse end, snap lock, or auto-lock tuck boxes, patch windows bring tangible value to a wide variety of industries.

In today’s competitive marketplace, first impressions matter, and packaging often serves as the first point of contact between a brand and its potential customer. A patch window allows customers to see the actual product inside the box—without compromising security or cleanliness. This transparency fosters consumer trust, especially for products where appearance, color, or condition play a critical role in the buying decision. For instance, customers buying cosmetics, baked goods, or handcrafted soaps rely heavily on what they can see. Patch windows offer that clarity while keeping the item protected from external elements.

The utility of patch windows extends across industries. A gourmet cookie brand can use a top patch window on an auto-lock tuck box to showcase fresh, delicious treats inside—enticing impulse buyers. A toy manufacturer might opt for a large PVC window on a snap lock tuck box to reveal a vibrant action figure, immediately capturing a child’s interest. For luxury cosmetics, a straight end tuck box with a clean, centered patch window can show off a beautifully designed lipstick or perfume bottle, enhancing the product’s elegance. Even industrial brands can benefit: auto parts, such as spark plugs or sensors, can be packaged in a reverse end tuck box with a clear window that confirms contents without opening, thus reducing error and returns.

Beyond appearance and functionality, patch windows can also align with a brand’s sustainability goals. Materials like biodegradable PLA film or recyclable PET are increasingly used to meet environmental standards while still providing crystal-clear visibility. When paired with eco-friendly printing and board materials, the entire package becomes a reflection of the brand’s values.

The success of window-patched packaging lies in the synergy between design and practicality. By carefully choosing the right type of tuck box, window shape, and film material, brands can turn a simple cardboard box into a compelling, retail-ready display that speaks directly to the customer. Ultimately, patch windows serve as a strategic touchpoint—they build excitement, showcase product quality, and support the broader mission of enhancing brand credibility in the retail space.