Introduction to Custom Magnetic Closure Boxes

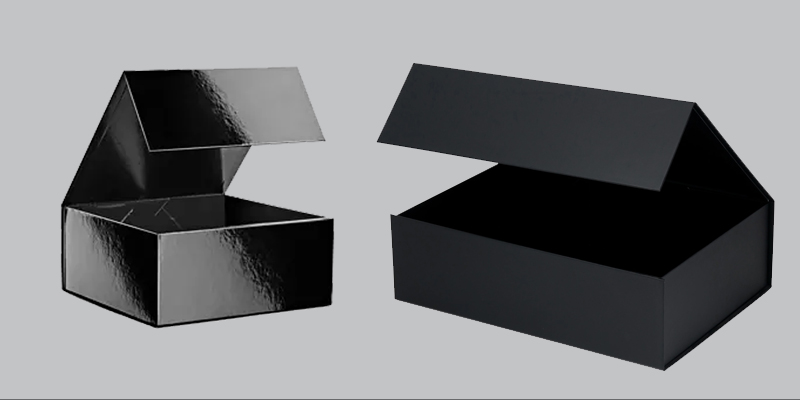

What Are Magnetic Closure Boxes?

Custom magnetic closure boxes are premium packaging solutions designed to offer both functionality and aesthetic appeal. These boxes feature a built-in magnet mechanism that ensures secure closure, making them ideal for high-end products, luxury items, and corporate gifting. The “custom” aspect means that businesses can tailor every element of the box—from size, shape, and material to printing, finishes, and internal inserts—to align with their brand identity and product requirements.

Customization allows brands to create unique unboxing experiences that leave a lasting impression on customers. Whether it’s a luxury watch, a high-value corporate gift, or a premium book launch, magnetic closure boxes elevate the perceived value of the product inside. However, the level of customization impacts the overall cost, with options ranging from simple collapsible boxes to high-end versions with foam inserts and specialty finishes.

What Are Custom Magnetic Closure Boxes used for?

The uses of custom magnetic closure boxes can vary substantially. They maybe used for gifts, product launches and so forth. Let us go through a grid of the different uses for magnetic closure boxes.

Luxury Watch & Jewelry Packaging

Watches and jewelry require secure and elegant packaging. Magnetic closure boxes not only protect delicate items but also provide a premium unboxing experience. The soft-close mechanism ensures the box doesn’t snap shut abruptly, preventing damage to the contents.

Perfume Packaging

Another popular use for Magnetic closure boxes is in the form of presenting samples of perfumes in high-end packaging. Although these are higher in cost but a lot of perfumery companies prefer this style of packaging to communicate a higher-end luxury feel.

Product Introductions & Launches

When a brand launches a new product, first impressions matter. A magnetic closure box adds a touch of sophistication, making the product feel exclusive. For example, a high-end skincare brand may use these boxes to enhance the perceived value of a new serum or cream.

Book Launches & Special Editions

Authors and publishers use custom magnetic closure boxes for limited-edition books, special collector’s editions, or high-value manuscripts. The box can be designed to include embossed titles, foil stamping, or even a window to showcase the book cover.

Our Custom Books Slipcases are also a great alternate to magnetic closure boxes for packaging books.

Corporate Gifts for High-Value Clients

Businesses often gift premium items (such as engraved pens, leather goods, or tech gadgets) to top clients. A magnetic closure box enhances the gifting experience, reinforcing the brand’s commitment to quality.

Real Estate & High-Ticket Item Promotions

Real estate agencies may use these boxes to present property brochures, keys, or miniature property models in an upscale manner. Similarly, high-ticket items like electronics or limited-edition collectibles benefit from the luxurious appeal of magnetic closure packaging.

Types of Custom Magnetic Closure Boxes

Depending on the purpose for which the Custom Magnetic Closure Boxes are to be used, there are 3 main types of Magnetic Closure Boxes.

Collapsible Magnetic Closure Boxes (Without Inserts)

These boxes are shipped flat and are easy to assemble. They are cost-effective and ideal for lightweight products. Usually these are used for retail packaging, subscription boxes, and products that don’t require extra cushioning. The resultant of that is reduced cost making these the most affordable option since they require minimal labor and materials.

Magnetic Closure Boxes with Card Inserts

These boxes include pre-cut cardboard inserts to hold the product in place. They offer better protection than collapsible boxes. Since these boxes are also shipped as flat & easy-to-assemble, they are widely used in industries such as cosmetics, small electronics, and mid-range luxury products.

Although these are not as expensive as the Custom Magnetic Closure Boxes with Foam Inserts but the cost is slightly higher than collapsible boxes due to additional material and cutting processes.

Magnetic Closure Boxes with Foam or EVA Foam Inserts

These boxes come fully assembled with precision-cut foam inserts that snugly fit the product, offering maximum protection. The best uses for these boxes can be seen for high-end watches, jewelry, fragile items, and premium corporate gifts.

Due to the labor and additional materials involved in the production of Custom Magnetic Closure Boxes with Foam Inserts, they inevitably cost more. They are typically 3 times more expensive than boxes without inserts due to labor-intensive foam cutting and assembly.

How to Infuse a Luxury Feel into Magnetic Closure Boxes?

Apart from the rigid materials used in the production of Custom Magnetic Closure Boxes there are various printing and finishing techniques that can be used to delineate a luxury feel to these magnetic closure wonders. Let’s take a look at each of them one at a time.

Matte & Soft Touch Finishes

They key difference between Matte and Gloss finishes is the light reflectivity of the paper sheet. If treated with matte finishing, the light reflection is considerably diminished. This in turn allows for a luxury overall feel to the box.Below you can see a comparison of gloss finish vs matte finish on magnetic closure boxes. It is pretty evident which one of these boxes communicates sophistication and luxury.

UV Spot Gloss

Spot UV printing is a premium finishing technique that enhances specific areas of a printed design with a high-gloss coating, creating a striking contrast against a matte or uncoated background.

This method uses ultraviolet (UV) light to cure the glossy varnish, ensuring durability and a sleek, professional look. Commonly applied to logos, text, or patterns, spot UV adds depth, texture, and visual appeal, making it a popular choice for business cards, packaging, and book covers. It not only elevates aesthetics but also provides a tactile experience that enhances brand perception.

Gold or Silver Foiling

Gold or Silver Foiling in printing is a decorative technique that applies a thin metallic foil layer onto a printed surface, creating a luxurious and unavoidably eye-catching finish. This process, also known as hot foil stamping, uses heat and pressure to transfer the foil onto paper, cardstock, or packaging materials.

Gold and silver foiling are commonly used in Magnetic Closure Boxes for logos, lettering, and decorative accents on business cards, book covers, invitations, and luxury packaging. The result is a shimmering, high-end effect that enhances branding and gives printed materials a premium, elegant look.

Debossing & Embossing

Embossing and debossing are premium finishing techniques used to add texture and dimension to custom magnetic closure boxes, enhancing their visual and tactile appeal.

1. Embossing raises specific design elements—such as logos, patterns, or text—above the surface of the box, creating a 3D effect. This adds a luxurious feel and makes the design stand out, especially when combined with foiling or spot UV.

2. Debossing, on the other hand, presses the design into the surface, creating a recessed effect. This technique gives a subtle yet elegant impression, adding depth and sophistication to the packaging.

Both methods enhance branding and create a premium, high-end look, making magnetic closure boxes ideal for luxury products, gift packaging, and exclusive branding.

Choosing the Right Finish based on Product Value

Below you will see our personal recommendations for various types of products to be packaged in the Custom Printed Magnetic Closure Boxes. These deductions are based on our past experience of delivering high-quality and also affordable magnetic closure boxes for our clients.

High-Dollar Value Items such as Luxury Watches, Jewelry, Tech Gadgets etc

Recommended: Matte/soft-touch finish with gold/silver foiling, foam inserts, and embossing.

Why? The packaging should match the exclusivity of the product.

Mid-Range Products such as Cosmetics, Perfumes, Books etc

Recommended: Glossy finish with offset printing and card inserts.

Why? Balances cost while maintaining a premium look.

For Corporate Gifts & Real Estate Launches

Recommended: Glossy or matte finish with simple branding and no foam inserts (unless gifting fragile items).

Why? Keeps costs conservative while still delivering a professional presentation.

How can I reduce the cost for Magnetic Closure Boxes?

Although, the purpose of Custom Magnetic Closure Gift Boxes is to communicate luxury and a rather majestic feel, it is important to know how to save on the cost end too. Lets take a look at the factors that contribute towards a higher cost for magnetic closure boxes.

1. Dimensions

The dimensions of a box are crucial to its sturdiness. The longer, wider and taller the box gets, the higher level of board thickness is needed to ensure a minimum level of sturdiness. If the dimensions (length, width and height) are between 4-10 inches, the 800GSM or 30-pt is good enough for the box construction.

Similarly, if the dimensions fall between 10-12 inches on either sides, we shift to 1000GSM or 60-pt. For boxes with dimensions larger than 12 inches on any side, the best bet is to use 1400GSM or above.

For a few of our clients, we have also gone as high as 1800GSM in order to ensure extreme sturdiness.

There are magnetic boxes made out of chipboard as well but that will be a really high-cost solution.

2. Finishes

Various types of finishes also aggregate towards a higher overall cost of the Magnetic Closure Boxes. Matte & Soft finishes, Spot UV foiling, Gold/Silver foiling, and debossing/embossing all are various processes that come with individual costs.

A rule of thumb in understanding the costs associated with these processes is that the more processes you will add to your box, the higher the costs will become. In a nutshell, each of these processes add between $ 0.50-2.50 to the overall cost of the boxes.

3. Inserts

Depending on what is to be presented inside the Magnetic Closure Rigid Boxes or Custom Magnetic Closure Gift Boxes, the need for having inserts oscillates between a yes or no. Since there are two different types of inserts, card and foam, the costs are also different.

Card inserts can increase the cost from $ 0.50-1.50. A key point to note here is that magnetic closure boxes with card inserts are shipped as Flat-easy to assemble also known as collapsible boxes.

The foam inserts are where the cost go up in multiples. If for example a magnetic closure box without inserts costs $ 10.00, just by adding foam inserts the cost can easily scoop up as high as $ 25.00-30.00 for each box.

This is because of labor costs of installing the inserts and also the boxes need to be shipped volumetric instead. Just because the box is shipped in volume, the shipping costs become high and it all adds up to the overall cost of the boxes.

These boxes with foam inserts can go really high for larger sized boxes. We have shipped boxes with foam inserts in higher dimensions such as 25″ x 20″ x 3.5″. This particular client is a world-renowned car manufacturer of luxury sports cars and the boxes with Spot-UV for the log and gold foiling including Eva-foam Inserts costed $ 149.00 each.

So to conclude, it is important to keep in mind that a box without inserts and only regular off-set printing is going to be a fraction in cost compared to a box with multiple processes and foam inserts.

So what is the take away?

It really varies from product to product, market to market, customer to customer, etc. The main idea is to get to speak to one of our product consultants or email us at orders@customboxesforless.com and allow us the opportunity to assist to the best of our years of knowledge so we can help you get your magnetic closure boxes right and make it affordable for you at the same time.